Liquid ring - single stage

The ASCO VACUUM TECHNOLOGY ALM and ALL liquid ring vacuum pump series are single stage type with vary port design. Simplicity and robustness are the main features of this high quality Italian designed and manufactured vacuum pump. The pump is available in a monoblock or an intermediate bracket option. ATEX version is also available.

Wide range of applications - High reliability & low maintenance - Possibility to handle almost any gas and vapour - Isothermal compression - Compact design with overhung impeller - One moving part : the impeller - Impeller and port plate in stainless steel even for the basic version - Different exotic material executions available (hastelloy, titanium, etc) - Oil free operation - Low vibration & silent running

-

Capacity (m3/h): 15 up to 480

-

Pressure range (mBar): 33 up to 1013 ( swith ejector up to 10 mBar )

-

Material execution: SS316, Duplex, SuperDuplex, Hastelloy, Titan, other on request

-

Aplications: Sterilization, Degassing, Evaporation/distillation, Priming, Vacuum industrial processing, Bottle filling, Depoultry, Extrusion, Oil & Gas

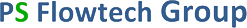

Liquid ring - two stage

The ASCO VACUUM TECHNOLOGY ALD and ALDL liquid ring vacuum pump series are two-stage type, for deep vacuum thanks to the optimization of the compression ratio between two impellers operating in series. These pumps are designed to provide the maximum efficiency at deep vacuum. Further vacuum can be achieved with ejectors. API 681 engineered upgrade available on request with various high-grade materials.

Complete line from 3 to 55 kW (11 models) - Wide range of applications - Possibility to handle almost any gas and vapour - Isothermal compression - In between bearing design - One moving part : the rotor - Impellers and port plates in stainless steel even for the basic version - API 681 engineered upgrade on request - Low maintenance - Low vibration and silent running - Oil free vibration

-

Capacity (m3/h): 40 up to 48 000

-

Suction pressure (mBar): 33 up to 1013 ( with ejector up to 7 mBar )

-

Material execution: SS316, Duplex, SuperDuplex, Hastelloy, Titan, other on request

-

Aplications: Sterilization, Degassing, Evaporation/distillation, Power generation, Vacuum industrial processing, Drying, Oil & Gas

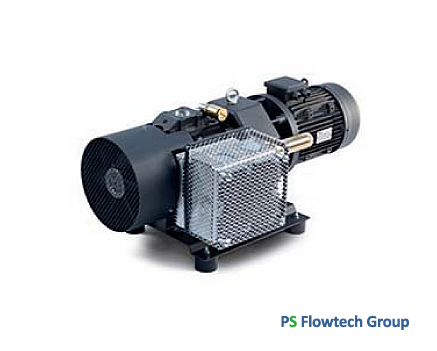

Rotary vane vacuum pump Oil-free

Oil-free dry vacuum pumps belonging to the DR range are blade rotary type, in between bearing rotor, flanged motor mounting suitable to operate without any lubrication through air cooling. Main features are heavy construction design, easy maintenance, absence of any oil fog on the discharge. The pumps are able to be used in any application where no deep vacuum is required.

Blade rotary type - In between bearing rotor - Operating without lubrication - Robust construction - Easy maintenance - Absence of oil midst on gas discharge

-

Capacity (m3/h): 3,5 up to 250

-

Vacuum (mBar abs): 150 up to 400

-

Aplication: Paper processing industry, Suction cups and grippers, Depalletizers, CNC machinery for wood or glass

Rotary vane vacuum pumps Oil-lubricated

Oil lubricated vacuum pumps with oil recirculation belonging to the OL range are blade rotary type, in between bearing rotor flanged motor mounting, automatically lubricated. Main features are heavy construction design, high performance and reliability, easy maintenance. The pumps are able to achieve the end vacuum of 2 or 0.5 mbar absolute depending on pump model.

High pump delivery also by very low pressure values - Very silent running, vibration free - No oil fog at the pump discharge - Efficient air cooling - Gas ballast valve - Robust & compact construction - Very easy maintenance - Pump supplied with mineral oil charge

-

Capacity (m3/h): 4 up to 700

-

Vacuum (mBar abs): 0,5 - 2 - 10

-

Aplications: Food packing, Thermoforming, Degassing, Pneumatic conveying

Centralized vacuum systems

Centralized vacuum units are normally installed in industrial plants that are in need of vacuum through a supply network, which servesseveral equipment simultaneously or in batches.

As the demand for vacuum might not be constant throughout the day, the system is equipped with one or more vacuum reservoir tanks to minimisefluctuations, while still being able to have more pumps working in parallel to meet process needs.

Proper monitoring using specificinstrumentations and operating logics will help achieve the required duty conditions, this would also lead to lower power consumption and energy savings.

Condenser exhausters

A typical application for liquid ring vacuum pumps is power generation, where main condensers have to be kept under vacuum through an air extraction system.

ASCO VACUUM TECHNOLOGY is in the position to offerhogging & holding units for both surface and air cooled condensers simply by having a wide range of pumps that can be combined with steam or gas ejectors in various ways. This applies to conventional plants and also nuclear and geothermal plants.

Surface condensers might require water box vacuum units, which are complementary to the mainsystems.

Vacuum systems

Packaged systems are designed uponcustomer's requirements and are equipped with ASCO VACUUM TECHNOLOGY's liquid ring vacuum pumps type AL-D (two stage) and AL-A (single stage, also in monoblock execution type AL-M or AL-L with lantern adaptor).

Both pumps and piping can be provided in either stainless steel or iron.

For oil and gas applications, pumps are manufactured according to API 681 (1st edition) standards.

ASCO VACUUM TECHNOLOGY is referenced by industry leaders such as GEA Group, Pirelli, Tecnimont, and OTV Veolia.

Pharma systems

Deep vacuum capability is needed in typical pharmaceutical applications. Distillation and drying processes in pharmaceutical applications often involve solvents with low boiling point, causing the liquid ring principle to be less suitable.

ASCO VACUUM TECHNOLOGY had created an innovative solution by proposing a hybrid system involving a dry screw vacuum pump system that allows solvent flushing for clean operation.

This rigid structure has two solid rotors, nickel or PTFE internal coating options, oil free operation, no metal to metal contact, and longlifebearings and gears. Gas sealed lip and labyrinth seals provide a reliable and energy efficient solution. ATEX standards are also fully met.